How To Keep Your Shed Weatherproof With Shed Roof Felt

Here is what you need to know about roofing felt...

Quick Navigation

While a wood garden shed might be the most aesthetically appealing and one of the more durable designs, even the best of sheds is only as good as the roof.

Roofing felt can be a good way to keep the inside of your shed dry, it is relatively easy to apply and requires very little in the way of tools or experience to install.

However, there are a few things I feel you should know before you rush out to your local home improvement superstore and plunk down a wad of cash on several rolls of shed roof felt or you could end up doing the whole job all over again.

Top Things You Should Know about Roofing Felt

Before we get too far into this, you should know that while shed roof felt is an economical and easy to install way to protect your wood shed roof, it is subject to blistering and cracking that can lead to leaks.

Depending on the climate where you live, you may find that using nothing but shed roof felt is not going to be enough to effectively seal and protect your shed’s roof and everything you have stored inside from rain, snow, and ice.

Tec Synthtic Felt - Image courtesy of Amazon

This being said, roofing felt can be a good way to seal your shed roof, but you may want to add a layer of shingles over the felt to create a more effective and longer lasting roof if you have room in your budget. At the same time, there are different types of shed roof felt to choose from, each of which has its problems and advantages.

Roofing felt is typically attached to the wood sheathing or clapboards using nails, this in and of itself creates a risk of water intrusion over time as the nails pull out under high winds or are pushed out as the wood expands and contracts with changes in temperature.

Roofing felt can also tear or be damaged for several reasons, including:

- High winds

- Ice buildup

- Tree branches

- Extremes in temperature

- Toys hitting the roof

- People climbing on the roof

Yet despite these potential issues with shed roof felt, it still makes an excellent way to waterproof your wood shed roof when you are working on a budget.

On top of this, it is one of the simplest forms of roofing to install as anyone who can use a few basic hand tools can replace the entire roof of their shed in a few short hours.

Different Types of Shed Roofing Felt

In the early days, roofing felt was typically made from rolls of paper that were impregnated with tar or bitumen that may or may not have been embedded with various minerals to help reduce the damaging effects of solar radiation.

This type of roof felt was considered to be relatively effective, but because it was made with a paper base, was prone to tearing under high winds.

Today most shed roof felt is made using either a fiberglass fleece or polyester base material as both of these materials are significantly stronger than paper.

Fiberglass Fleece

Fiberglass fleece roofing - Image courtesy of Archi Expo

Shed roof felt made with a fiberglass fleece base are considered to be among the strongest and longest lasting in the industry. These roofing felts are known for their ability to withstand tearing and to hold up under extremes in weather.

The fiberglass fleece is impregnated with a tar-like substance called bitumen that makes the fleece waterproof.

Polyester Fibers

Polyester roofing felt - Image courtesy of Archi Expo

In recent years a new type of roofing felt has been developed using polyester fibers as the base material.

Much like fiberglass based felt, polyester based felts have a high resistance to tearing and is capable of handling extremes in weather. It is also impregnated with bitumen that makes it waterproof.

This type of shed roof felt does not last as long as the fiberglass variety.

An Organic Option

Organic roofing felt - Image courtesy of Tarco

The final option that may be available in your area is completely organic roofing felt. This type of roofing felt is made from fibers of rags. The base material is then soaked in asphalt to make it waterproof while still retaining the organic qualities, the reason why so many people choose this option.

Much like the polyester based felt, this type of felt does not currently have the same durability and lifespan of fiberglass.

Recent Improvements in Roofing Felt

As with just about everything today, even roofing felt is going high-tech. Today’s roofing felts have been designed to be better at sealing around the nails used to secure them to your roof.

Many of the new materials weigh less than their traditional counterparts and are offered in sheets that are up to 36-inches wide. Some of these improvements have increased the cost of roofing felt, but their durability and the reduction in the number of seams you end up with are well worth the added cost.

Many rolls of roofing felt now come with lines marked on them to speed up the overlapping process and help you keep everything straight, which is vital to not only doing a professional installation job but also in making your roof as tight and waterproof as possible.

One thing to keep in mind as you look at the different types of roof felt for your shed is that if you are not adding shingles on top of the felt, you need to choose felt that has a mineral-based surface.

A Word about Weight and Warranties

All types of roofing felt, including shed roof felt are listed and sold by their “weight”, which is in effect the manufacturer’s way of describing its thickness. Roofing felts are sold in a number of weights with 15 lb. or 30 lb. weights being the most common.

30-lb. felt is thicker than 15 lb. You should base your choice on the size of your shed roof and the climate you live in. Bear in mind that the thicker felt will last far longer and be able to withstand extremes in both heat and cold.

Each manufacturer offers its own range of warranties based on the type of felt you are buying, its thickness, any coatings, and numerous other factors. Be sure to read the warranty on any shed roof felt you are thinking about buying.

While there is a number of inexpensive “shed roof” felts on the market, you will be much better off buying roofing felt that is made for use on houses as it is much stronger. The difference in cost is easily offset by their durability longevity.

How Much Shed Roof Felt Do You Need?

Now that you have a good idea of the different types of shed roof felt available, it is time to look at how much you need to buy. This is a relatively easy process that starts by measuring the full size of your roof.

You will need enough felt to run the entire length of your roof plus an extra 2-3 inches at each end for the overlap.

Synthetic Roll Roofing Underlayment - Image courtesy of Amazon

You will also need an additional length for the crown of your roof, bear in mind that in order to effectively seal your roof, the felt must be laid perfectly flat and in overlapping layers.

Roof felt is sold in rolls, most of which are now 36 inches wide and come in a variety of lengths. Choose rolls that allow you to cut the maximum possible number of single sheets out of the roll with minimal waste.

Which One Should I Buy?

With so many different brands on the market, it can be hard to know which one you should buy.

The one thing that most professional roofers will tell you up front, is that you should avoid those so-called “shed” felts as they are literally “paper thin” and while inexpensive, they do not stand up well, especially in high winds and because of this are not considered to be worth the money.

Here are some of the best ones I could find for you to consider.

1. Tamko Roof Felt

Lightweight, Inexpensive Underlayment Roof felt

This is an organic felt that is saturated in asphalt that measures a full 36 inches wide by 144 inches long. It is 15 lb. felt that is black in color. Worth noting is that this is asphalt saturated organic mat, but it does not have a mineral coating to help make it more weather resistant.

Each roll contains enough felt to cover 4 squares of roof or 432 sq. feet. According to the manufacturer, this roofing felt is intended for use as an underlayment, meaning you should plan to cover it with shingles for optimum performance.

Pros | Cons |

|---|---|

Very inexpensive | 15 lb. weight is thin, will rip easily |

Large rolls | Has no mineral coating for protection from the weather |

Easy to install and work with | Not made for use without shingles |

2. Orgill Roofing Felt 15RF

Top of the Line 15 lb. Roofing Felt

Although this roofing felt may be more expensive than the same weight of felt from Tamko, the asphalt saturated felt is made from highly flexible organic fibers that make it much easier to install, but very strong at the same time.

By virtue of its design, this shed roof felt is more resistant to tearing during installation or in moderate winds. It comes in rolls that are 36 inches wide by 12 feet long. Once again this felt is intended to be used as an underlayment rather than as the final covering for your shed roof.

Pros | Cons |

|---|---|

Strong organic mat construction | Relatively expensive for 15 lb. felt |

Rip resistant | Must have a layer of shingles for maximum protection |

336 x 144-inch rolls | Has no mineral coating for protection from the weather |

3. TARCO 90LB BRN MineralRoofing

All the Way at the Other End of the Spectrum

If 15 lb. shed roof felt is at the bottom end of the scale when it comes to roofing felt, then 90 lb. felt is surely at the top. This particular felt from TARCO is made from asphalt impregnated organic materials.

What makes the difference is that this felt is mineral coated, making it a good choice for anyone who is looking for a felt that can be used as a final roofing rather than one that should be used solely as an underlayment. Rolls measure 36 by 144 inches.

Pros | Cons |

|---|---|

90 lb. weight is much better for overall protection | 90 lb. weight can be challenging to work with |

Mineral coating is ideal for maximum weatherproofing | Rolls weigh 72 pounds making them very heavy to move around |

36 x 144 rolls provide plenty of coverage | Rolls are somewhat expensive as is shipping |

4. BlueHawk Sand Finish Roof Felt 5m

Sand finish for Added Traction and Protection

This felt from BlueHawk is designed specifically for use on shed roofs and comes in rolls that are 5 meters long and 1 meter wide. It is manufactured in the U.K. to withstand typical British weather, making it ideal for use in rainy areas of the U.S.

The felt itself uses an organic recycled rag fiber with an oxidized bitumen coating that is infused with sand. This felt is a 15 lb. (7 kg.) thickness which is easy to handle and install.

Pros | Cons |

|---|---|

Sand finish for better weather resistance | 15 lb. weight not ideal for high winds |

15 lb. weight is easy to handle | Higher initial cost per roll |

Low shipping costs | Designed to be an outer layer or underlayment |

How Do You Attach the Shed Roof Felt to Your Shed?

Attaching the shed roof felt to your shed is relatively easy and the average shed roof can be covered in a couple of hours or so with the most basic of hand tools and a little patience.

Tools and Materials Needed

Like every other aspect of building your shed, there are a number of materials and tools needed to install shed roof felt. So here is a good basic list of the tools and materials you are going to need:

- Roofing felt

- Roofing nails short and long

- Hammer

- Tape measure

- Box knife with hook blade (you can use a straight blade, but a hooked blade is easier to work with)

- Straight edge (a 36-inch long steel ruler or level works best)

There really isn’t that much to installing felt roofing, but the job still takes a certain amount of skill and dedication to the job at hand.

One note on the hook style blade. A hook blade will not cut into the surface you have the felt laid out on for cutting, whereas a straight blade will. Most expert roofers also say that using a hook blade makes cutting roofing felt much easier.

Step by Step Shed Roof Felt Installation

Here is a basic step by step covering how to install your shed roof felt and achieve the best results along with a video that you can see here covering installing your shed roof felt.

- Measure the length and width of your roof and calculate the total area. (the average roll covers 432 square feet. Hint: area of a rectangle is length x width.

- Clean the wood surface of the roof, removing any debris, nails that are sticking out, or anything else that will damage the new felt.

- Be sure the entire surface is dry, you should never apply new felt on a wet wood surface as this can cause the wood to warp, crack, or rot.

- If your shed roof has any damaged or rotted wood, now is the time to replace it.

- Cut lengths of shed roof felt to match the long side of the roof, be sure to add 2 to 3 inches to the length at each end. This extra length will be folded over and nailed to the battens so that any water will drip off the edge without getting the wood wet.

- Tack one end of the felt in place so that it remains in place as you roll it out.

- Roll the full length out and pull it tight without ripping it while at the same time making sure it is perfectly flat.

- Nail the felt using roofing nails. You should use short nails that are not going to puncture the wood for the surface and longer nails for the drip edge to help hold it more firmly in place. You should place nails at 2-inch intervals on the surface and 3-inch intervals on the drip edges.

- Pull the edges over tight and nail in place, fold the corners to help maintain the watertight seal.

- Whether you are installing just a crown piece or need to add extra runs of felt, you should use a quality cement between the layers to add a better seal.

- You may want to cover the nail heads with mastic or roofing tar for a better seal.

- Stand back and enjoy your new roof.

Related Products

If your shed roof is already covered with roofing felt that is not quite ready for replacement, but showing signs of leakage, you may be able to make it last a little longer with a special type of paint such as this one:

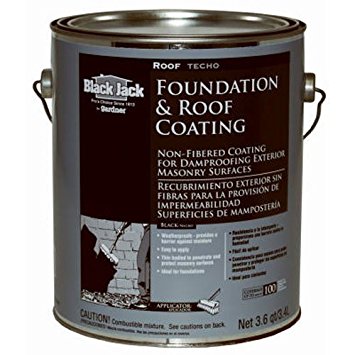

Gardner-Gibson 6025-9-34 3.6QT NF Roof Coating

Highly Durable Roof and Foundation Coating

This is a non-fibered refined asphalt base coating that is perfect for adding a protective coating for many types of roofing felt. It can also be used to seal metal roofs and wood surfaces. By using this paint, you can add months or even years to the life of your shed roof felt.

Pros | Cons |

|---|---|

Saves you from replacing your shed roof felt | Messy to work with |

Very inexpensive | Long dry time |

Can be used on multiple surfaces | Only comes in black |

If you would like more information on the various different types of shed roof materials, take a look here where we have already done most of the research for you.

Topping It All Off

I hope you have enjoyed reading the information we have assembled for you here on shed roof felt. Finding the right felt might seem like a major challenge, but the information here would have made my first attempt at replacing my shed roof much simpler, so I hope it does for you.

Be sure to watch the video as it contains lots of very helpful tips.

If you liked what I have put together for you here, please let me know.

Let everyone know you enjoyed reading this on Facebook, Twitter, and Pinterest.

Thank you for reading this.

Related Articles: